Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Shock Absorber For Mitsubishi 341141

Shock Absorber Production Process for Mitsubishi 341141:

Raw Material Selection: The process begins with the careful selection of high-quality raw materials, including high-strength steel for the shock absorber's main components. These materials are chosen for their durability and ability to withstand various road conditions.

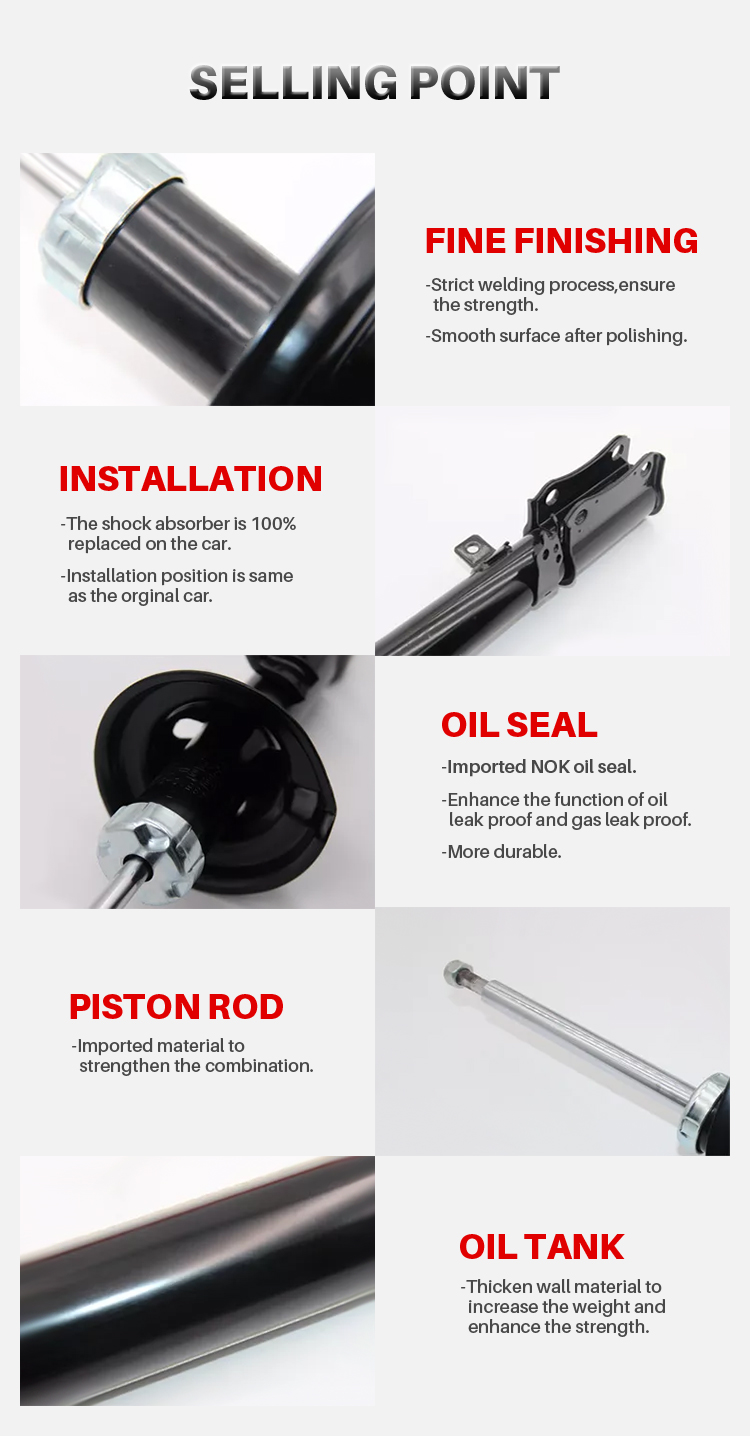

Machining the Piston Rod: The piston rod, a crucial component of the shock absorber, undergoes precision machining to achieve a smooth surface finish. This process ensures that the rod moves seamlessly within the shock absorber's cylinder.

Component Manufacturing: Various components, such as the outer housing, seals, and mounting brackets, are manufactured to precise specifications. Each component is crafted to meet the shock absorber's design requirements.

Assembling the Shock Absorber: During assembly, the piston rod, seals, and other internal components are carefully integrated into the shock absorber's housing. The shock absorber's damping mechanism is also installed during this step.

Testing and Quality Control: Every shock absorber undergoes rigorous testing to ensure its performance meets quality standards. This includes evaluating its damping capabilities, leak resistance, and overall functionality. Any units that do not meet the specified criteria are rejected.

Surface Treatment: The shock absorber's external surfaces may receive coatings or treatments to enhance corrosion resistance and improve aesthetics. This step helps protect the shock absorber from environmental factors.

Packaging: Once the shock absorber passes quality control, it is prepared for packaging. Packaging may vary depending on customer requirements, and each shock absorber is typically labeled with its model number and other relevant information.

Shipping: The finished shock absorbers are ready for shipment to various distribution points or directly to customers. They are packed securely to prevent damage during transportation.

Documentation: Detailed documentation, including specifications, quality control records, and compliance certificates, is maintained for each shock absorber batch.

Throughout the entire production process, strict adherence to quality control measures and compliance with international standards, such as ISO 9001, ensure that the Mitsubishi 341141 Shock Absorber meets the highest quality and performance expectations.